68fordguy wrote:Ok we'll I have time to figure out what I'm going to do because in ct here were in a foot of snow and 20 degree weather right now plus it's a dd now so I'll wait another month or so before I do suspension and think it would be easiest when the trucks all apart and I'm restoring it this summer when I'm off. But so then I'll just re register my 2wd shortbed and drive that but I have to wait to do that anyway until I figure out what I'm doing for a transmission to run behind my 428CJ. I'm so eager to tear the Highboy down but I'm really enjoying dd it and wheelin it now haha. anyway i have been pretty set on the superduty springs for a while and I wouldn't mind a little lift but I think if I run 33ats for the most part on the road but also want to be able to put 35s or even 37s military's under it in the future. So if I put the 4 in procomp springs on the front I need to move the rear hangers back and when I fab up the front crossmember hitch deal with those measurements I should be all set? And also of course longer shocks and u bolt. Then in the rear you just put add a leafs?

Sorry to keep making you restate this stuff just with all the adjustments and fails and everything it gets confusing haha. And also if I did just want to run the stock superdutys first then switch to the 4" what do I have to do with the hangers?

Thanks again man

-Scott

Yeah, 4-6" springs (different sites list different amounts of lift... i can get the number off of my springs so you know which springs i have). You don't move the rear hanger back. It's imbedded into the frame, that would be a hell of a project. You just need to make longer shackles. Not sure how much longer mine are over stock but i can measure mine. New u-bolts and new shocks of course. For the shocks, i couldn't find decent peg to peg style shocks in the correct length so I got peg to eyeley conversion bracket deals for the bottom of the shocks (at the axle) and got eyelet to peg style shocks. Yeah the rear of mine is stock leaf springs with added leaf springs. It's funny... the rear flexes way more than the front procomp springs do. With all the wheeling (lots of rubicon trips planned) the truck will see this summer, I'm going to start re-designing the suspension on this thing to get it to flex more both front and rear.

If you ran stock superdutys then the lift springs, you would just need to change shocks, and possibly shackles depending on how long you made them for the stock superduty springs.

Also don't forget about driveline length when lifting the truck up. I re-tubed my front driveline with .250 wall tubing and had it dialed perfectly with no balancing. Good idea to take it to a driveline shop though if you dont have the right tools.

koch68 wrote:I am building a front hitch like yours and have got to the point of building the front hangers any sugestions? Should I put then a little bit more forward then stock since im using superduty springs also?

I already forget exactly where i put the front spring holes in relation to stock, but i know they are about an inch lower than stock due to the crossmember sitting under the frame, and i do believe i moved the hole forward a half inch or so...

KRob wrote:Ryan,

I cant seem to find what your doing suspension wise now. Im thinking about 37 military tires as well and i am curious what i would have to do to get there.

Thanks

Rob

The above replies should help a little. I"ll try my best to remember to get various measurements tomorrow along with the leaf spring part number and such to help you guys out. Wish i could remember more!

Zukinut wrote:Ryan,

Do you mind if I send you a pm, this next winter the f350 is going under the knife. It's getting a front 60 and a cummins. The cummins isn't an issue with me, but front suspension is.

Your truck is beyond badass.

Will

Go for it!

I've been busy... 6-10 hours of work every night. Although half of this goes to my other project.

Ran a tap through every single threaded hole on the trucks body tonight. Getting ready to put the front clip all back on.

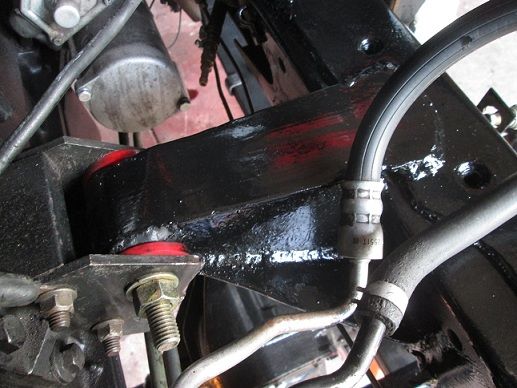

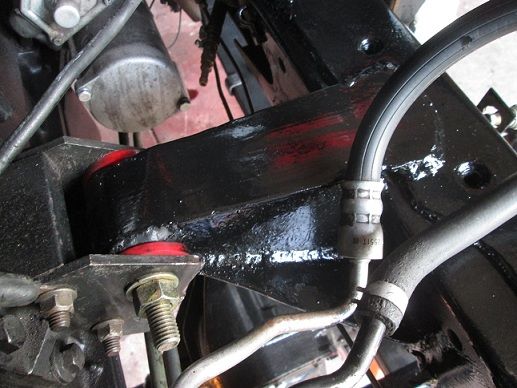

Plated in the mounts finally. Been putting it off for so long because of how hard it is to get the gun anywhere near the joint to weld. I managed.

and had a buddy throw some parts in the sandblasting booth the other day

.

This is what has been taking up countless hours and just under $2k now. 9" i'm almost done building for the other truck. Getting that truck ready to race this season. Very excited.. and broke.

.

.